Bitumen for Cold Climate

Bitumen for Cold Climate: The Cornerstone of Durable Infrastructure

Bitumen for cold climate applications serves as the cornerstone of durable infrastructure in regions experiencing extreme temperature variations. This specialized material must maintain flexibility at temperatures as low as -40°C while still providing adequate stiffness during warmer periods. Without properly formulated cold climate bitumen, roads in northern regions would quickly deteriorate under the constant stress of freezing and thawing cycles.

The importance of selecting appropriate cold climate bitumen cannot be overstated. Traditional bitumen grades typically become brittle in frigid conditions, leading to thermal cracking and accelerated deterioration of road surfaces. By contrast, cold-formulated bitumen maintains critical viscoelastic properties even in extreme conditions, extending pavement life by years and significantly reducing maintenance costs over time.

Road authorities in cold regions face unique challenges that their counterparts in temperate zones rarely encounter. Snow removal operations, studded tire usage, and the application of de-icing chemicals all compound the stress on bituminous pavements. Only specially engineered cold climate bitumen can withstand this combination of mechanical, thermal, and chemical stresses while maintaining structural integrity throughout the winter season and beyond.

Understanding Bitumen: Basics and Origins

Understanding bitumen begins with recognizing its basic composition and origins as a complex hydrocarbon material. Derived primarily as a residual product from petroleum distillation, bitumen consists of thousands of different chemical compounds, predominantly asphaltenes and maltenes, which give it its characteristic adhesive properties and viscoelastic behavior.

The geological origins of bitumen stretch back millions of years, as organic materials underwent transformation under pressure and heat. Modern bitumen production typically occurs in oil refineries through the vacuum distillation of crude oil, where the heaviest fractions are separated and processed. The quality and performance characteristics of bitumen vary significantly depending on the source crude oil, with some sources naturally producing bitumen better suited for cold climate applications.

Chemically speaking, bitumen is not a simple material but rather a colloidal system where asphaltenes are dispersed within an oily medium of maltenes. This complex structure determines how bitumen responds to temperature changes—a critical factor when considering its application in cold environments. Understanding these fundamental properties provides the necessary foundation for appreciating why certain bitumen formulations perform better than others in frigid conditions.

Why Cold Climate Bitumen is Special

Why cold climate bitumen is special comes down to its unique formulation designed specifically to maintain flexibility at extremely low temperatures. Unlike standard bitumen grades that become brittle when cold, specialized cold climate formulations retain critical elasticity even when thermometers drop well below freezing. This exceptional performance stems from careful engineering of the material’s molecular structure and the inclusion of specialized additives.

Cold climate bitumen exhibits a significantly lower glass transition temperature—the point at which the material changes from a rubber-like state to a glass-like rigidity. Standard bitumen might reach this critical transition point at temperatures around -10°C to -20°C, while cold climate variants maintain elasticity at temperatures as low as -40°C. This dramatic difference represents the difference between a road surface that cracks under winter stress and one that flexes and recovers.

The specialized nature of cold climate bitumen also encompasses its ability to handle rapid temperature fluctuations, which are common in many northern regions where daytime warming can quickly give way to freezing nights. This thermal cyclic resilience prevents the formation of microcracks that would otherwise propagate and expand through repeated freeze-thaw cycles, ultimately leading to premature pavement failure.

Performance Grading of Bitumen for Cold Regions

Performance grading of bitumen for cold regions follows the Super pave PG (Performance Grade) system, which categorizes bitumen based on the temperature extremes it can withstand while maintaining adequate performance. For example, a PG 58-34 bitumen performs reliably at temperatures ranging from 58°C (high temperature) down to -34°C (low temperature). This scientific approach to classification ensures that road engineers select materials appropriate for specific local climate conditions.

The low-temperature performance grade is particularly critical for cold climate applications, as it indicates the lowest temperature at which the bitumen can resist thermal cracking. Testing procedures include the Bending Beam Rheometer (BBR) test, which measures stiffness and relaxation properties at low temperatures, and the Direct Tension Test (DTT), which evaluates the material’s ability to withstand strain without cracking in cold conditions.

Cold region performance grading must account for the extreme conditions these materials will face. A bitumen that performs adequately in laboratory conditions might still fail prematurely if the actual field temperatures exceed the design parameters or if additional stressors like heavy traffic loads combine with thermal stress. For this reason, experienced engineers often specify bitumen with a low-temperature grade that exceeds minimum requirements by at least 10°C as a safety margin.

| Performance Grade | High Temperature | Low Temperature | Typical Applications |

| PG 58-34 | 58°C | -34°C | Cold regions, low to moderate traffic |

| PG 58-40 | 58°C | -40°C | Very cold regions, low traffic |

| PG 64-34 | 64°C | -34°C | Cold climates, moderate traffic |

| PG 64-40 | 64°C | -40°C | Very cold regions, moderate traffic |

| PG 70-28 | 70°C | -28°C | Cold regions with higher traffic |

| PG 76-28 | 76°C | -28°C | Cold regions with high traffic, harsh winters |

The Role of Polymers in Enhancing Bitumen Flexibility

The role of polymers in enhancing bitumen flexibility cannot be overstated when discussing cold climate applications. Polymer modification represents one of the most significant advancements in bitumen technology, allowing for dramatic improvements in low-temperature performance. These polymer-modified bitumen (PMBs) incorporate materials such as styrene-butadiene-styrene (SBS), ethylene-vinyl-acetate (EVA), or polyethylene to create a crosslinked network that enhances elasticity and resilience.

Polymers function by forming a three-dimensional network within the bitumen matrix, fundamentally altering how the material responds to stress and temperature changes. This polymer network provides elastic memory, allowing the bitumen to stretch under load or temperature change and then return to its original configuration without permanent deformation. In cold climates, this property is invaluable for preventing the formation of thermal cracks that would otherwise occur as the pavement contracts.

Scientific studies have demonstrated that properly formulated polymer-modified bitumen can lower the effective glass transition temperature by 15°C or more compared to conventional bitumen. This remarkable improvement translates directly to better field performance, with properly designed PMB pavements showing significantly fewer thermal cracks and longer service life in cold regions. The additional cost of polymer modification typically represents an excellent investment when considering the extended pavement life and reduced maintenance costs.

Application Techniques of Bitumen in Frigid Zones

Application techniques of bitumen in frigid zones require specialized approaches that account for the challenging environmental conditions. Construction seasons in cold climate regions are often compressed into a few short months, creating pressure to optimize every aspect of the application process. Proper handling begins with maintaining bitumen at appropriate temperatures during transport and storage, using insulated tanks and heating systems to prevent premature cooling.

The paving process itself must be carefully managed, with close attention paid to ambient temperature conditions. Most cold climate paving specifications require minimum air and surface temperatures before work can proceed, typically at least 10°C with rising temperatures. Compact windows of opportunity make logistics planning crucial, with contractors often working extended hours during favorable weather conditions to complete projects.

Achieving proper compaction presents another significant challenge in cold environments, as the bitumen cools more rapidly than in temperate conditions. This accelerated cooling reduces the time available for compaction, potentially leading to inadequate density if not properly managed. Advanced techniques such as the use of warm mix technologies, additional rollers, and carefully planned laying patterns help ensure that the material achieves optimal density before cooling below effective compaction temperatures.

Addressing Common Problems: Cracking and Rutting

Addressing common problems like cracking and rutting requires understanding their root causes in cold climate pavements. Thermal cracking occurs when pavement temperatures drop rapidly, causing the bitumen to contract faster than the aggregate structure can accommodate. These cracks typically appear as transverse fractures across the roadway at regular intervals and represent one of the most prevalent failure modes in cold regions.

Rutting, while often associated with high temperatures, can also occur in cold climate pavements during spring thaw periods when the underlying structure weakens due to excess moisture. The combination of weakened support and traffic loading creates permanent deformation in the wheel paths. Properly formulated cold climate bitumen helps resist both thermal cracking through enhanced low-temperature flexibility and rutting through appropriate stiffness at moderate temperatures.

Prevention strategies incorporate both material selection and structural design elements. Multi-layer pavement systems with carefully selected bitumen grades for each layer can provide an optimal balance of properties. Surface layers might use highly polymer-modified bitumen with exceptional cold resistance, while lower layers might focus more on structural support. Additionally, proper drainage design prevents moisture accumulation that would otherwise exacerbate thaw weakening and accelerate rutting development.

Innovative Additives and Their Impact on Bitumen Properties

Innovative additives have revolutionized bitumen properties for cold climate applications, extending performance boundaries beyond what was previously possible. Beyond polymer modification, today’s cutting-edge formulations incorporate a range of specialized additives including polyphosphoric acid (PPA), waxes, chemical modifiers, and nanomaterials, each bringing unique benefits to cold weather performance.

Anti-stripping agents represent a crucial category of additives for cold regions where moisture damage is prevalent. These compounds improve the adhesion between bitumen and aggregate, preventing water from penetrating the interface and causing adhesive failure. This is particularly important in freeze-thaw environments where water expansion during freezing creates additional stress at these critical interfaces.

Nanomaterial additives represent the frontier of bitumen technology, with research showing promising results from incorporating materials such as Nano clays, carbon nanotubes, and graphene. These nanoscale additives can dramatically improve rheological properties, oxidation resistance, and thermal stability even at very low dosage rates. While still emerging as commercial products, these Nano-enhanced bitumen show exceptional promise for creating ultra-durable pavements for the harshest cold environments.

Environmental Concerns: Sustainable Bitumen Production

Environmental concerns around sustainable bitumen production have grown increasingly important as the construction industry faces pressure to reduce its carbon footprint. Traditional bitumen production is energy-intensive, with significant greenhouse gas emissions associated with the heating and processing required. For cold climate applications, this environmental impact can be even greater due to the specialized processing and additives required.

The sustainability challenge has spurred innovation in bitumen production methods, including lower-temperature production techniques that reduce energy consumption and emissions. Warm mix asphalt technologies, which allow production and placement at temperatures 20-40°C lower than conventional hot mix, represent an important advancement in reducing the environmental impact while often improving cold-weather compaction properties.

Recycling of existing pavement materials through processes like reclaimed asphalt pavement (RAP) utilization and full-depth reclamation provides another pathway to more sustainable cold climate bitumen usage. These approaches reduce the demand for virgin materials while often delivering performance comparable to or better than conventional methods. The key challenge lies in properly rejuvenating the aged bitumen in recycled materials to restore its cold weather flexibility—a focus of ongoing research and development efforts.

Global Case Studies: Successes in Cold Climate Road Construction

Global case studies highlighting successes in cold climate road construction demonstrate the real-world effectiveness of specialized bitumen formulations. In northern Canada, the Alaska Highway reconstruction project between Fort St. John and Fort Nelson utilized highly modified PG 58-34 bitumen with SBS polymers and anti-stripping additives to withstand temperatures that regularly drop below -40°C. After ten years in service, these pavements continue to show significantly better performance than previous conventional installations.

Scandinavian countries have pioneered many cold climate bitumen technologies, with Norway’s use of highly polymer-modified bitumen on mountain passes like Hardangervidda showing exceptional durability despite extreme weather conditions. Their approach combines carefully selected aggregate materials with specialized bitumen formulations and rigorous quality control during construction, creating pavements that withstand heavy snowplow activity and studded tire usage with minimal damage.

Russia’s experience with the Yakutsk Highway in eastern Siberia represents perhaps the ultimate test case for cold climate bitumen. Built on permafrost with winter temperatures reaching -60°C, this project utilized advanced polymer-modified bitumen with specially developed Arctic-grade additives. Construction techniques included extended seasonal monitoring and adaptive design approaches that have allowed the roadway to maintain functionality despite facing some of the most extreme temperature variations on Earth.

Future Trends: The Road Ahead for Cold Climate Bitumen

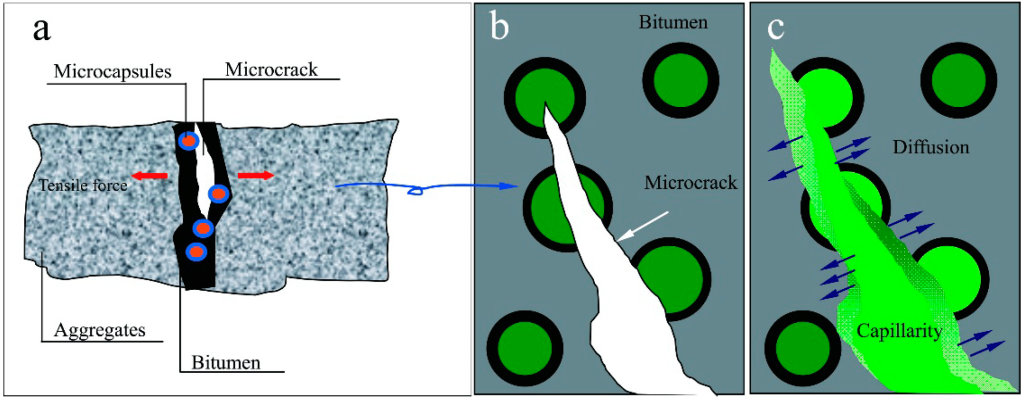

Future trends in cold climate bitumen technology point toward even more resilient and environmentally sustainable solutions. Self-healing bitumen represents one of the most promising frontiers, incorporating microcapsules containing rejuvenating agents or using reversible polymer networks that can repair microcracks before they propagate into larger failures. These technologies could dramatically extend pavement life in cold regions by addressing damage at its earliest stages.

Climate change considerations are increasingly influencing cold climate bitumen formulation as regions experience more extreme weather events and greater temperature fluctuations. Future bitumen grades may need expanded performance ranges to handle both colder winter extremes and hotter summer conditions within the same pavement system. This has accelerated interest in multiple polymer modification systems that provide both excellent low-temperature flexibility and high-temperature stability.

Digitalization and smart infrastructure integration represent another emerging trend, with embedded sensors monitoring pavement temperature, strain, and moisture conditions in real-time. These systems allow for predictive maintenance and performance validation of new bitumen formulations under actual field conditions. As this technology becomes more cost-effective, it promises to revolutionize how we evaluate and improve cold climate bitumen performance through continuous feedback and adaptation.

Conclusion

The evolution of cold climate bitumen technology represents one of the most significant advancements in infrastructure resilience for northern regions. Through careful engineering of base materials, innovative additive packages, and specialized application techniques, modern cold climate bitumen formulations enable roadways to withstand conditions that would have rapidly destroyed pavements of previous generations.

As climate patterns continue to change and infrastructure demands increase, the ongoing development of even more capable cold climate bitumen will remain essential. By combining traditional knowledge with cutting-edge materials science, the industry continues to push the boundaries of what’s possible in creating durable, sustainable pavements for the world’s coldest environments.

For engineers, contractors, and road authorities working in cold regions, staying informed about these advances isn’t just professionally important—it’s essential for delivering infrastructure that performs reliably through the harshest winters while providing value for public investment. The future of cold climate bitumen looks promising, with innovation driving both performance improvement and environmental sustainability in this critical infrastructure material.

For engineers, contractors, and road construction officials, becoming familiar with these innovations is not only professionally important but also essential for providing reliable and valuable infrastructure for public investment. The future of cold climate bitumen is promising, with innovation serving better performance and greater sustainability. At Gulf Petro Vision, we have the capability to supply any grade of bitumen suitable for different weather conditions with the highest quality and tailored to the specific needs of your project.