Bitumen Applications-Waterproofing Membranes

Introduction to Bitumen Waterproofing Membranes

Bitumen waterproofing membranes represent one of the most effective solutions for protecting structures against water infiltration. These versatile products, primarily manufactured using standard 60/70 penetration grade bitumen, have revolutionized the construction industry’s approach to waterproofing. The development of these membranes stems from the need to provide reliable, long-lasting protection for various building components, including roofs, foundations, and underground structures.

Waterproofing membranes based on bitumen have evolved significantly over the decades, incorporating advanced polymers and reinforcement materials to enhance their performance characteristics. The global market for these products continues to expand, with analysts projecting steady growth through 2025 driven by increased construction activities and greater awareness of building envelope protection requirements.

Manufacturing Process of Bitumen Waterproofing Membranes

The manufacturing process of bitumen waterproofing membranes involves several sophisticated steps designed to create a product that delivers consistent performance. The process typically begins with the selection and preparation of appropriate bitumen, usually the standard 60/70 penetration grade, which serves as the primary waterproofing component.

Modern manufacturing facilities employ the following process sequence:

- Base Material Preparation: Reinforcement carriers such as polyester, fiberglass, or composite materials are unwound from large rolls and inspected for defects.

- Bitumen Compounding: Raw bitumen is modified with polymers (SBS, APP) and other additives in large mixing vessels at controlled temperatures (typically 180-200°C).

- Impregnation: The reinforcement material passes through an impregnation bath containing hot modified bitumen.

- Coating Application: Additional layers of modified bitumen are applied to both sides of the impregnated reinforcement.

- Surface Finishing: Various surfacing materials (mineral granules, sand, polyethylene film) are applied to prevent sticking during storage.

- Cooling and Winding: The continuous sheet is cooled using water-cooled rollers and wound into rolls of specified dimensions.

- Quality Control Testing: Samples are tested for tensile strength, elongation, flexibility, and waterproofing capabilities.

According to the International Waterproofing Association (a general reference that can be linked), the manufacturing process must maintain strict temperature controls to preserve the optimum properties of the modified bitumen compounds throughout production.

Bitumen Consumption Percentage in Membrane Manufacturing

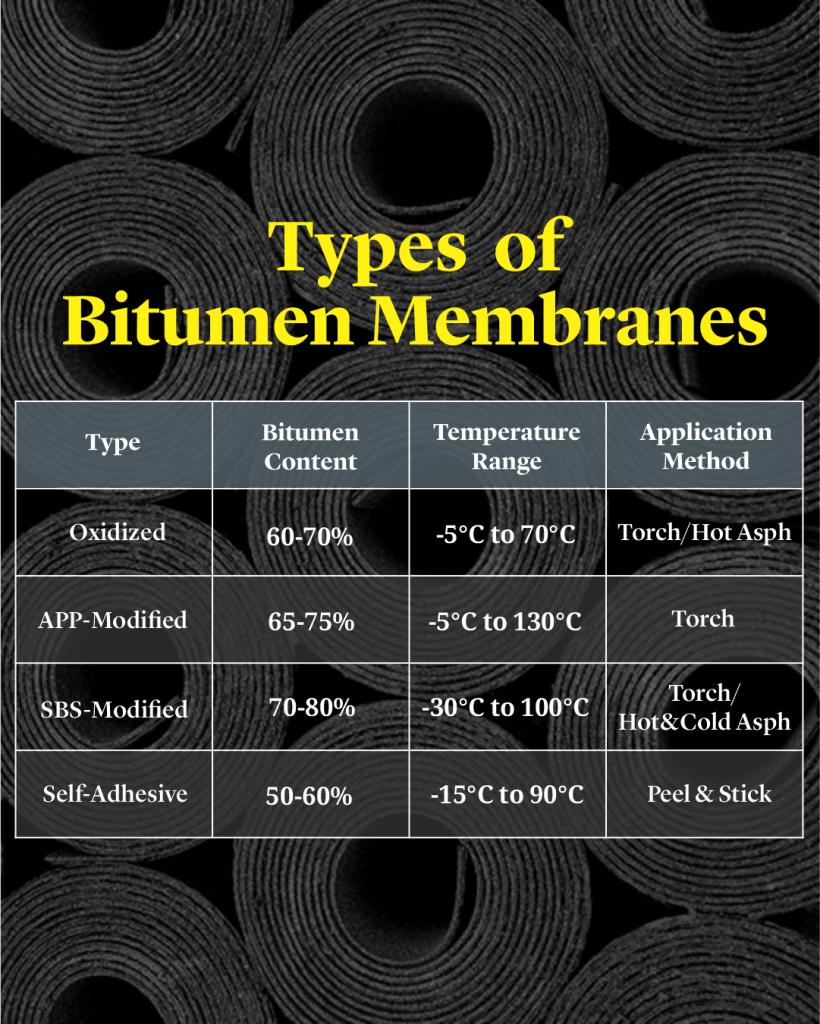

Bitumen consumption percentage in membrane manufacturing varies depending on the membrane type and its intended application. The bitumen content significantly influences the membrane’s performance characteristics, including flexibility, durability, and waterproofing capability.

Typical bitumen consumption percentages include:

- Standard Oxidized Bitumen Membranes: 60-70% bitumen content by weight

- APP-Modified Membranes: 65-75% bitumen combined with 25-35% atactic polypropylene and stabilizers

- SBS-Modified Membranes: 70-80% bitumen combined with 12-15% styrene-butadiene-styrene polymer

- Self-Adhesive Membranes: 50-60% bitumen with additional tackifying resins and elastomers

The remainder of the membrane composition consists of reinforcement materials, fillers, stabilizers, and surfacing elements. Higher-quality membranes generally contain a greater percentage of polymer-modified bitumen to enhance elastic recovery, cold flexibility, and aging resistance properties.

Types of Bitumen Membranes and Their Differences

Reinforcement Materials in Bitumen Membranes

Reinforcement materials in bitumen membranes provide structural integrity and dimensional stability. The choice of reinforcement significantly impacts the membrane’s performance and suitability for specific applications.

Fiberglass Reinforcement

Fiberglass reinforcement provides excellent dimensional stability with minimal elongation. Membranes with fiberglass reinforcement typically exhibit:

- High puncture resistance

- Limited flexibility (1-2% elongation)

- Excellent fire resistance properties

- Superior resistance to thermal cycling

Polyester Reinforcement

Polyester reinforcement delivers enhanced mechanical properties with greater elasticity. These membranes feature:

- Exceptional tensile strength (700-900 N/5cm)

- High elongation capabilities (40-50%)

- Superior resistance to fatigue and dynamic movement

- Better puncture and tear resistance

Composite Reinforcement

Composite reinforcement combines polyester and fiberglass to optimize the benefits of both materials. These hybrid membranes offer:

- Balanced dimensional stability and flexibility

- Enhanced durability under varied stress conditions

- Superior performance in complex applications

- Extended service life expectancy

Advantages of Bitumen Waterproofing Membranes

Advantages of bitumen waterproofing membranes make them a preferred choice for many construction professionals worldwide. These benefits contribute to their continued popularity despite the emergence of alternative waterproofing technologies.

- Proven Performance: With decades of documented successful installations, bitumen membranes have established reliability across diverse climatic conditions.

- Exceptional Water Resistance: Properly installed bitumen membranes provide complete impermeability to water, with redundant protection through multiple layers.

- Durability: Quality bitumen membranes demonstrate impressive longevity, with service life expectations ranging from 15-25 years depending on the specific formulation and installation.

- Application Versatility: These membranes can be applied to virtually any construction substrate, including concrete, metal, wood, and existing roofing materials.

- Self-Healing Properties: Certain modified bitumen formulations exhibit limited self-healing capabilities for minor punctures and small damage.

- Thermal Performance: Dark-colored bitumen membranes can contribute to energy efficiency in cold climates by absorbing solar heat.

- Chemical Resistance: Bitumen membranes demonstrate excellent resistance to common environmental contaminants, including dilute acids and alkalis.

Disadvantages and Limitations of Bitumen Membranes

Disadvantages and limitations of bitumen membranes must be considered when evaluating waterproofing solutions for specific projects. Understanding these constraints ensures appropriate application and installation.

- UV Sensitivity: Unprotected bitumen degrades under prolonged ultraviolet exposure, necessitating granular surfacing or reflective coatings for exposed applications.

- Temperature Constraints: Standard (non-modified) bitumen membranes become brittle in cold temperatures and may flow or deform in extreme heat.

- Installation Complexity: Proper installation requires specialized equipment and skilled labor to ensure watertight seams and proper attachment.

- Environmental Considerations: Traditional hot-applied membranes produce volatile organic compounds (VOCs) during installation, though newer formulations have reduced these emissions.

- Weight Factors: Multiple-ply bitumen membrane systems can add significant weight to structural loads, particularly important in re-roofing applications.

- Recycling Challenges: End-of-life disposal presents challenges, as bitumen membranes are difficult to recycle economically with current technologies.

Application Methods for Bitumen Waterproofing Membranes

Application methods for bitumen waterproofing membranes vary depending on the membrane type, project requirements, and environmental conditions. Proper installation is crucial for realizing the full performance potential of these systems.

Torch-Applied Method

The torch-applied method involves heating the underside of the membrane with a propane torch to melt the bitumen compound, creating adhesion to the substrate. This method:

- Creates strong adhesion through heat fusion

- Allows rapid installation in suitable weather conditions

- Requires certified operators for fire safety

- Works effectively in temperatures above 5°C

Self-Adhesive Application

Self-adhesive application eliminates open flames by utilizing factory-applied pressure-sensitive adhesive layers. This method:

- Provides safer installation in sensitive areas

- Requires careful substrate preparation and priming

- Works best in temperature ranges of 10-35°C

- May need supplemental heat in colder conditions

Cold-Applied Adhesive Method

Cold-applied adhesive method uses specially formulated bituminous adhesives to bond the membrane to the substrate. This approach:

- Eliminates fire hazards associated with torching

- Produces fewer VOC emissions during installation

- Allows application in temperature-sensitive areas

- Generally requires longer curing times

Hot Asphalt Application

Hot asphalt application employs heated asphalt as the adhesive between membrane layers and substrates. This traditional method:

- Creates monolithic waterproofing system

- Provides excellent adhesion to prepared surfaces

- Requires specialized equipment for asphalt heating

- Involves careful temperature monitoring during application

Quality Control and Testing Standards

Quality control and testing standards ensure that manufactured bitumen membranes meet specified performance criteria. These standards establish minimum requirements for physical properties, durability, and waterproofing capability.

Key testing parameters include:

- Tensile Strength and Elongation: ASTM D5147 establishes minimum requirements for membrane strength and elasticity.

- Low-Temperature Flexibility: EN 1109 assesses the membrane’s ability to resist cracking when bent at cold temperatures.

- Heat Resistance: ASTM D5147 and EN 1110 evaluate dimensional stability and flow resistance at elevated temperatures.

- Water Tightness: ASTM D5147 confirms absolute impermeability under hydrostatic pressure.

- Puncture Resistance: ASTM E154 measures the membrane’s ability to withstand static and dynamic puncture forces.

- Dimensional Stability: ASTM D5147 evaluates the membrane’s resistance to shrinkage and expansion under thermal cycling.

Manufacturers typically subject their products to these standardized tests and publish technical data sheets documenting compliance with regional building codes and industry standards.

Future Trends in Bitumen Membrane Technology

Future trends in bitumen membrane technology focus on improving performance, sustainability, and installation efficiency. Innovation continues to drive the evolution of these traditional waterproofing materials.

Emerging developments include:

- Bio-Based Modifiers: Research into replacing petroleum-based polymers with sustainable alternatives derived from renewable resources.

- Self-Healing Formulations: Advanced additives that enhance the membrane’s ability to repair minor damage autonomously.

- Cool Roof Technologies: Highly reflective surfacing options that reduce urban heat island effects and improve building energy efficiency.

- Integrated Photovoltaic Capabilities: Membranes designed to accommodate or incorporate solar energy collection systems.

- Enhanced Fire Resistance: New formulations with improved fire resistance properties to meet increasingly stringent building safety codes.

- Digital Manufacturing Controls: Implementation of Industry 4.0 technologies for more precise quality control and customization.

Conclusion

Bitumen waterproofing membranes continue to serve as essential components in modern construction, providing reliable protection against water infiltration across diverse applications. With advanced polymer modifications, sophisticated manufacturing processes, and continuous innovation, these products deliver exceptional performance and longevity when properly specified and installed.

The versatility of bitumen membranes, available in various formulations with different reinforcement materials and application methods, allows architects and contractors to select optimal solutions for specific project requirements. While alternative waterproofing technologies continue to emerge, the proven track record and ongoing evolution of bitumen membrane systems ensure their continued relevance in contemporary construction practices.

As the industry addresses sustainability challenges and improves manufacturing efficiency, bitumen waterproofing membranes will likely remain a cornerstone technology in building envelope protection, adapting to meet changing performance requirements and environmental considerations.